The bend allowance is the amount of the neutral axis that bends.

Sheet metal bend relief calculator.

Swfobj src http sheetmetal me wp content uploads 2011 05 bend allowance calculator swf width 395 height 180 bend allowance formula.

The bend allowance added to the flange lengths is equal to the total flat length of the part.

Our sheet metal fabrication process unlike traditional sheet metal shops we have infinite capacity and an easy to use online quoting system ensuring on time shipment every time whether you need a single part or 500 parts.

This page also includes a link to a on line sheet metal bend allowance calculator.

Note that the bend angle is the excluded angle not the included angle.

Cells on the right will output the desired values.

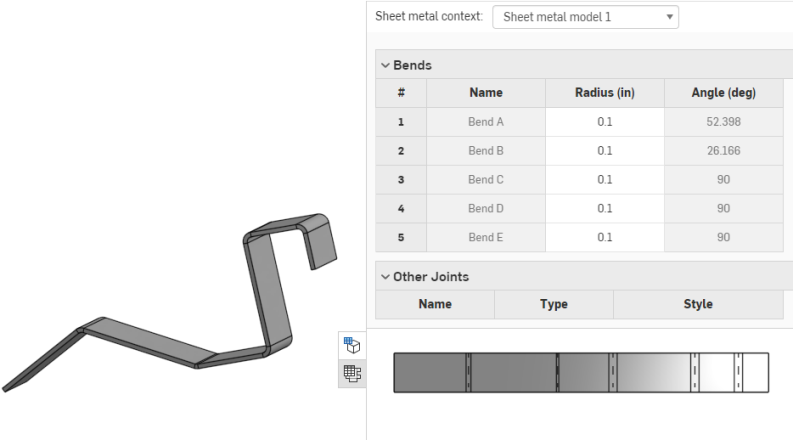

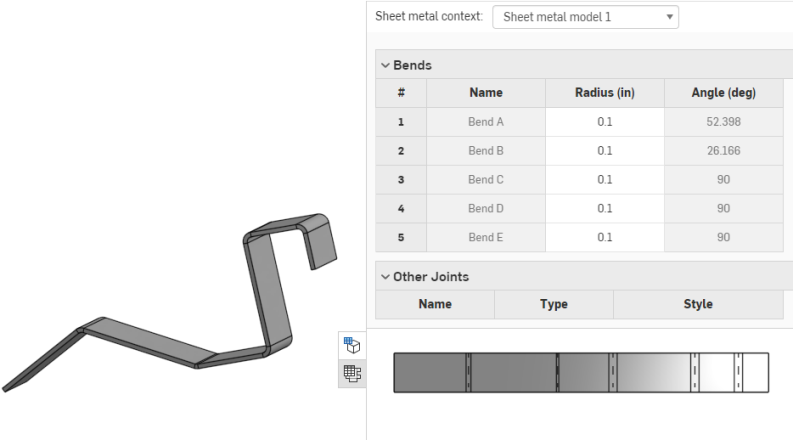

The following illustration shows the equation calculation for determining the bend allowance when forming sheet metal.

Although it is an option for calculating a bend in some cad programs such as solid works it is not often referred to in the actual manufacturing process since.

Geometry of tooling imposes a minimum bend dimension.

Refer to the chart for values for folder as well as various press brake tooling combinations.

Use the minimum bend dimension values in the charts below for your minimum closeness of cutout to a bend.

The diagram shows one such mechanism.

You only have to insert interior angle flange lengths k factor inside radius and material thickness.

Most sheet metal materials will conform to the calculations.

Sheet metal bend allowance calculator determines the bend allowance amount of metal to be added to the total layout when forming sheet metal.

Sheet metal calculator bend allowance equations and calculator.

Bend allowance calculator the bend allowance and bend deduction are two measures that relate the bent length of a piece of sheet metal to the flat length.

The bend allowance describes the length of the neutral axis between the bend lines or in other words the arc length of the bend.

With this free online tool we quickly get the sheet metal bend deduction and therefore the sheet metal blank initial flat length from the finished part measurements.

It simply processes these variables through the equations we will discuss below.

You also have access to our team of knowledgeable engineers to optimize part designs and user friendly online resources.

Therefore the bend deduction equals the difference between the mold line lengths and the total flat length.

Below is our simple bend allowance calculator it works by inputing the material thickness bend angle inside radius and k factor.

Most sheet metal materials will conform to the calculations.